Overview and Summary

Overview of Current State Practices

Pavement smoothness specifications vary greatly from state to state. Most states have different specifications for portland cement concrete (PCC) pavements and hot-mix asphalt (HMA) pavements, and these specifications are generally varied further according to the facility type and posted speed limit. States also have very different requirements for “exclusions” or areas which are exempt from smoothness testing, such as near bridges, intersections, driveways, or other areas where paving operations may be interrupted.

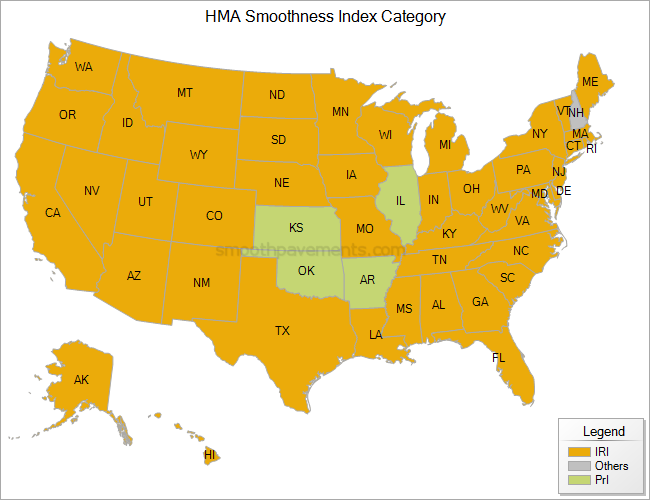

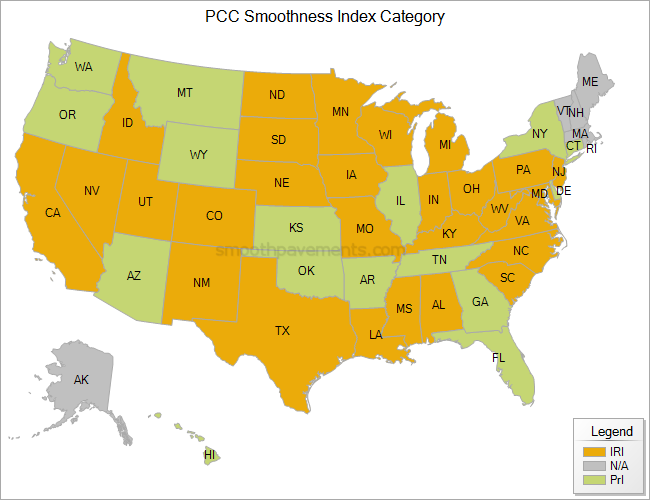

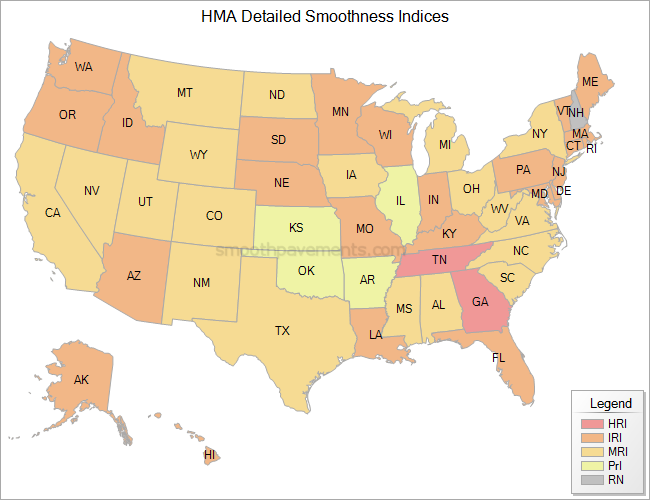

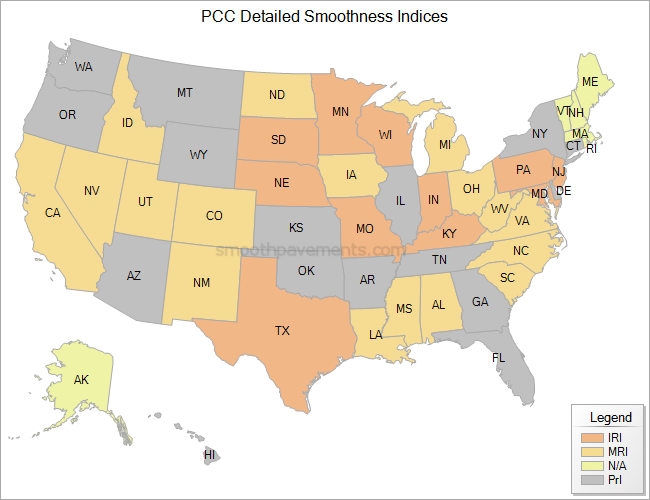

What is presented below is a simplified summary of current state smoothness specifications, with HMA and PCC pavement specifications shown separately. In general, these specifications are applicable to mainline, high-speed highway facilities. For details on the applicability of each state’s smoothness specifications, please refer to the standard specifications for the state.

Summary

The following are summaries of current State practices in smoothness specifications.

- Smoothness Index Categories: breakdown among IRI, non-IRI smoothness indices

- Detailed Smoothness Indices: detailed breakdown of all smoothness indices

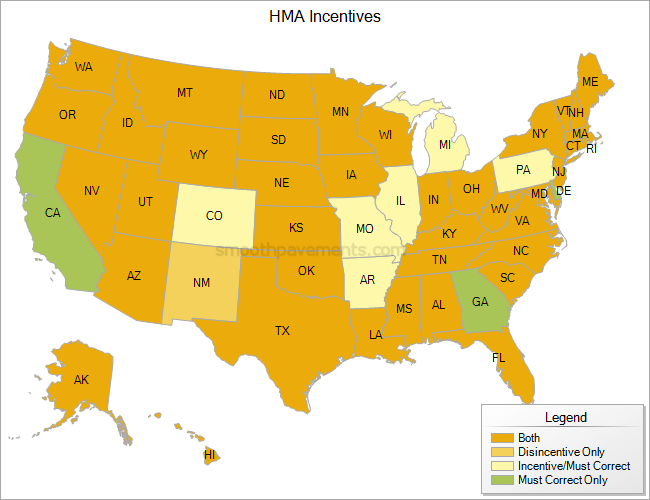

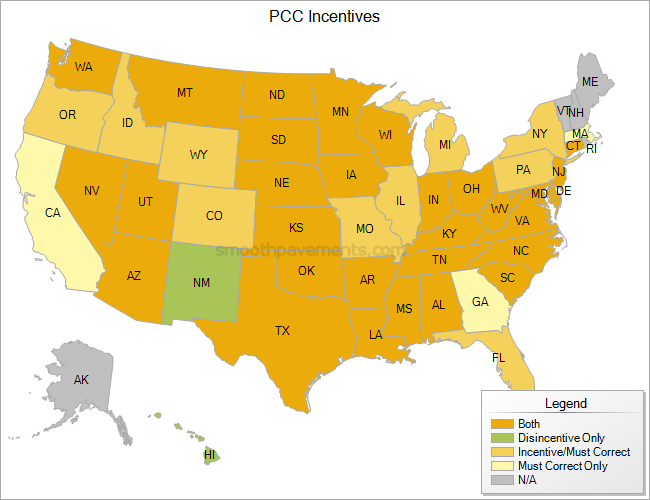

- Incentives/Disincentives: pay adjustments for smoothness provided in the specifications

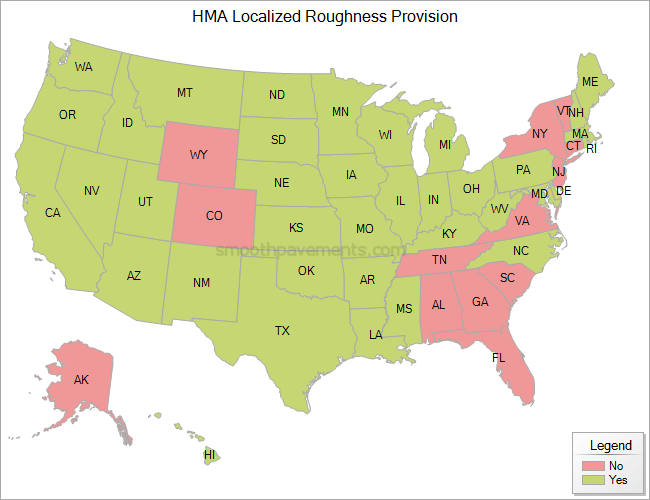

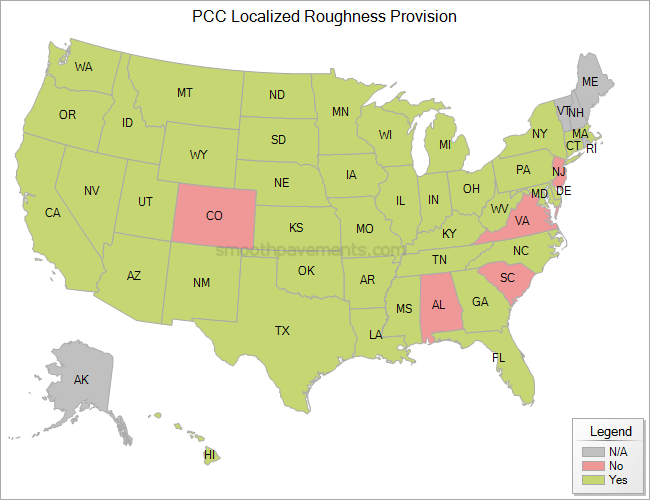

- Localized Roughness Provision: specific localized roughness provisions contained within smoothness specifications (including both bump/dip identification using profilograph/straightedge devices and localized roughness identification using inertial profiler devices)

For the breakdown between IRI and non-IRI smoothness indices, MRI and HRI are considered to be in the same category as IRI. Indices are noted as “Others” if they do not fall into either the IRI or PrI categories. “N/A” indicates that a state lacks a formal smoothness specification, even though a straightedge provision may be provided in the paving specifications.

Most states provide pay adjustments (incentives and disincentives) for pavement smoothness. These pay adjustments are generally only applicable to new construction, although some states also provide pay adjustments for rehabilitation operations such as diamond grinding (PCC), overlays (HMA), and mill and inlays (HMA). For the sake of simplicity, the Incentive/Disincentive summaries shown below are for new construction and/or full reconstruction. It should be noted that incentives and disincentives are generally based on initial smoothness measurement, prior to any corrective work, although some states do permit incentives to be paid after corrective work. Pay adjustments have been broken down into the following categories:

- Both: both incentive and disincentive pay adjustment schedules are provided

- Disincentive Only: no incentives are provided, just disincentives for out-of-spec areas

- Incentive/Must Correct: incentives are provided, but out-of-spec areas must be corrected

- Must Correct Only: neither incentives or disincentives are provided and the out-of-spec areas must be corrected

- N/A: no smoothness specifications or no information is available on incentives and disincentives

Please note that while "localized roughness" (defined by the roughness profile) and "bumps and dips" (defined by a bump template for a profilograph trace or rolling straightedge trace) are fundamentally different, the summaries presented on this site for "localized roughness provision" imply either the above definitions. Further breakdown of these provisions will be provided in the future.